PR325A Thermocouple Calibration Furnace

PR325A Thermocouple Calibration Furnace has excellent performance and rich functions. It adopts a new structural design, has a longer service life, and solves the problems of furnace positioning and high temperature electric leakage through the built-in metal positioner.

The control part uses part of the technology of the PR330 Multi-zone Temperature Calibration Furnace, which has the ability to adjust the axial temperature uniformity slightly. Compared with the traditional thermocouple calibration furnace, better verification or calibration results can be obtained without a isothermal block.

I. Features

No need for aisothermalblock, and the axial temperature uniformity over the full range is better than 1°C/6cm

The controller can automatically adjust the balance power at both ends, and can obtain 1°C/6cm axial temperature uniformity without a isothermal block in the temperature range of 300°C~1200°C, which can effectively reduce the uncertainty of the verification or calibration process.

Integrated high-accuracy temperature controller and reference compensator

Using PR2601 temperature controller, it has a measurement accuracy of 0.01. With the special reference end compensator, the accuracy is better than 0.6℃+0.1%RD when using type N temperature-controlled thermocouple.

Built-in positioner for easy sensor positioning

The bottom of the built-in metal positioner is 32cm away from the test end of the furnace mouth, and the furnace loading operation can be completed by simply inserting the sensor into the bottom of the positioner.

High temperature electric leakage suppression

The ground terminal is reserved externally, and after connecting the metal positioner, the influence of leakage at high temperature on the electrical measuring instrument can be effectively suppressed.

Longer service life

Under the same operating conditions, by increasing the load capacity of the internal heating wire, the service life of several times the traditional calibration furnace can be obtained.

Rich software and hardware functions

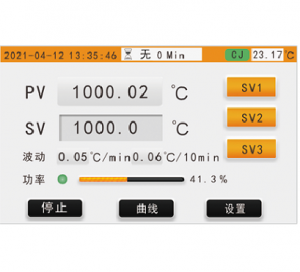

Using the front color touch screen, it can display and set general measurement and control parameters, and can also perform operations such as timed power on and off, temperature stability settings, and WIFI settings.

II. OtherFunctions

| Other Functions | |

| Temperature control sensor multi-temperature point correctionAdaptive temperature control parametersReal-time temperature, power curve display

Built-in reference junction compensation |

Custom temperature fluctuation calculationCustom alarm temperature upper and lower limitsBluetooth, WIFI expandable

Optional units °C, °F, K |

Product selection and technical parameters

| Model | PR325A | Remarks |

| Working temperature range | 300℃~1200℃ | / |

| Furnacecavity dimension | φ40mm×600mm | / |

| Temperature control accuracy | 0.5℃, when ≤500℃ 0.1%RD, when>500℃ | Geometric center point temperature of the furnacecavity |

| 60mm axial temperature field uniformity | ≤1.0℃ | 300℃~1200℃ Furnacecavitygeometric center ±30mm |

| Radial temperature field uniformity | ≤0.4℃ | Furnacecavitygeometric center |

| Temperature stability | ≤0.3℃/10min | / |

General technical parameters

| Item | Parameters |

| Dimensions | 700×370×500mm (L×W×H) |

| Display screen | 4.0-inch industrial touch screen with a resolution of 800×480 pixels |

| Communication method | RS232 (Standard), WiFi, Bluetooth (Optional) |

| Weight | 55kg |

| Rated power | 3kW |

| Power supply | 220VAC±10% |

| Working environment | -5~35℃,0~80%RH,Non-condensing |

| Storage environment | -20~70℃,0~80%RH,Non-condensing |